Imagine a construction crew building a bridge in the middle of nowhere, or a repair technician needing to fix heavy machinery deep within a manufacturing plant. What’s the common thread? The need for reliable power, both to weld and to run essential tools, regardless of grid access. This is where welder generators become indispensable workhorses, combining robust welding capabilities with the versatility of a portable power source. From towering skyscrapers to precision aerospace components, these powerful units are silently powering the progress that shapes our modern world.

The global market for portable welder generators is on a rapid ascent, projected to hit an impressive $1.3 billion by 2025. This growth isn't just a trend; it's a testament to the increasing demand for flexibility, mobility, and self-sufficiency in welding operations across virtually every major industry. If you're involved in any field that requires joining metal, understanding the diverse applications and industries where these machines shine isn't just useful—it's essential for smart project planning and execution.

At a Glance: Why Welder Generators Matter

- Mobile Powerhouses: Deliver welding and power generation where the grid can't reach.

- Boost Productivity: Minimize downtime by providing on-site power for tools and welding.

- Cost-Efficient: Reduce reliance on external power and rentals, often more fuel-efficient.

- Multi-Functional: Weld, power tools, and even serve as backup power during outages.

- Critical Across Industries: From construction to aerospace, they're fundamental to modern fabrication.

- Key Selection Factors: Choose based on power, fuel, portability, durability, and safety features.

The Unsung Heroes: What Makes Welder Generators So Crucial?

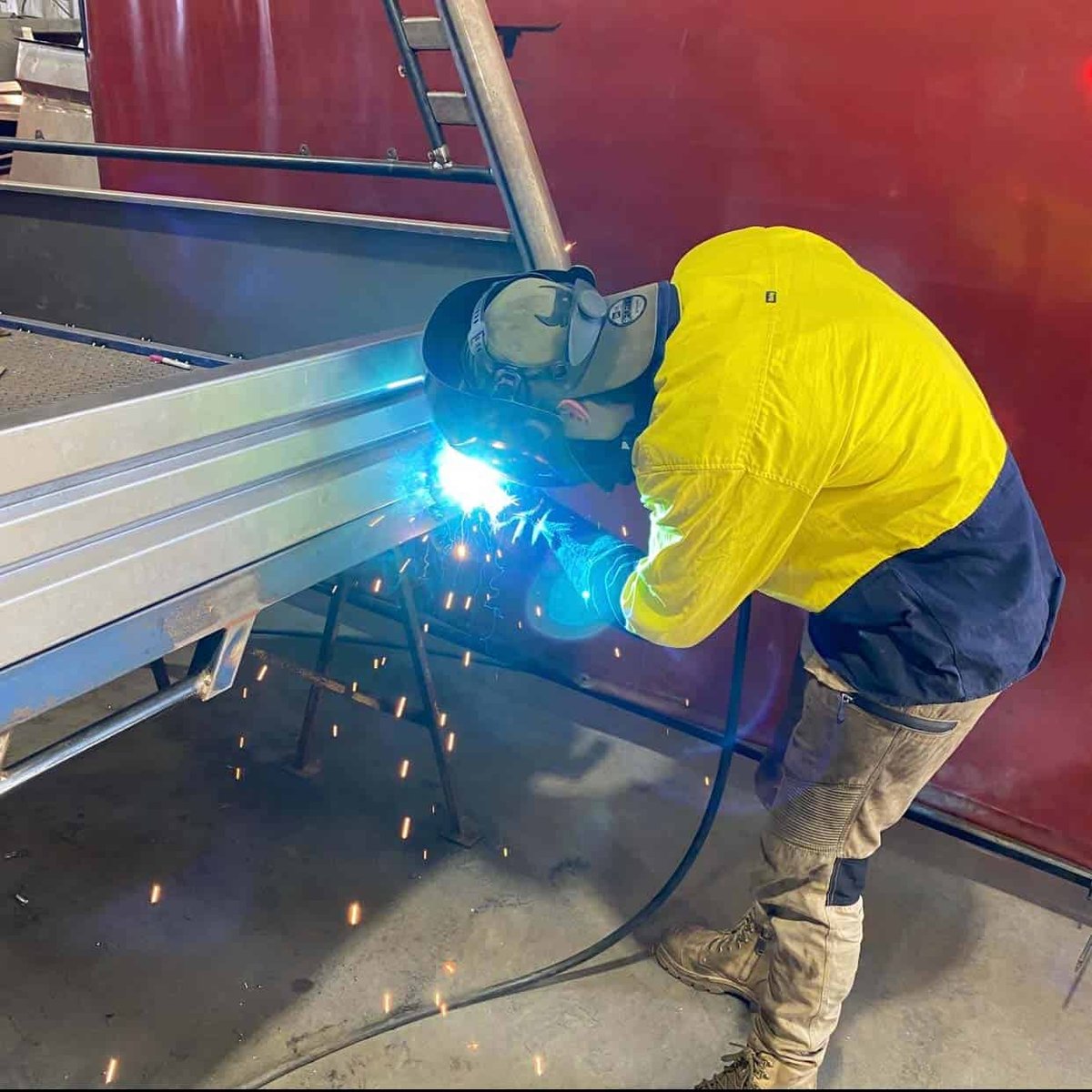

At its core, a welder generator is a dual-purpose machine: an arc welder and an electrical generator rolled into one portable package. This ingenious combination addresses a fundamental challenge in many industrial and commercial settings: how to perform high-quality welding in locations without easy access to mains electricity.

These units aren't just for emergencies; they're designed for daily grind in demanding environments. Think about the advantages: you can perform critical structural welds on a new pipeline miles from the nearest town, power your grinders and drills while working on a remote farm, or even keep essential equipment running during a power outage. Their ability to deliver consistent, reliable power for both welding and general electrical needs is a game-changer, increasing productivity by reducing equipment downtime and streamlining workflows.

Many modern units are also designed with efficiency in mind, often achieving up to 30% energy reduction compared to traditional setups. This doesn't just cut down on fuel costs; it also means a smaller environmental footprint—a win for both your wallet and the planet. Ultimately, the economic advantages of owning a robust welder generator often outweigh the initial investment, making them a savvy choice for businesses and independent contractors alike.

Navigating the Hurdles: What to Consider

While incredibly valuable, owning a welder generator isn't without its considerations. The upfront cost can be significant, ranging from hundreds to thousands of dollars depending on power output and features. Like any heavy machinery, these units also demand regular maintenance to ensure longevity and peak performance. You'll need to stay on top of oil changes, air filter replacements, and spark plug checks.

Most importantly, safety is paramount. Operating powerful electrical and welding equipment carries inherent risks. Improper operation can lead to severe accidents, making a thorough understanding of safety protocols and proper grounding essential. Always prioritize operator training and adherence to manufacturer guidelines to mitigate these concerns. If you're looking for a deeper dive into the world of these versatile machines, be sure to check out our Comprehensive welder generator guide.

Powering Progress: Industries Relied on Welder Generators

Welding is the backbone of modern industry. It's so fundamental, in fact, that it contributes to nearly 50% of the U.S. gross national product and is used in 70% of manufactured products. The global welding market, valued at $24.73 billion in 2023, is projected to surge to $34.18 billion by 2030. This growth is directly tied to the need for robust, reliable connections that only welding can provide, and in many cases, portable welder generators are the silent enablers of this critical work.

Let's explore some of the key sectors where these machines make an undeniable impact.

Construction & Infrastructure: Building Our World

From the towering skeletons of skyscrapers to the sprawling networks of bridges, pipelines, and rail systems, construction projects demand immense structural strength and durability. Welder generators are absolutely foundational here, ensuring that critical connections are made on-site, often in challenging, remote, or temporary locations. Nearly 50% of global steel production used in construction relies on welding to form its structures.

Imagine a crew installing new steel beams for a bridge renovation or fabricating custom railings at a new commercial building site. Running hundreds of feet of extension cords or relying on a temporary power grid simply isn't feasible or safe. Welder generators step in, providing the necessary amps for stick welding, MIG, and flux-cored arc welding—the workhorses of heavy construction. They also power auxiliary tools like angle grinders, cutting saws, and air compressors, keeping the entire operation moving smoothly. The versatility of a unit like the Lincoln Electric Ranger 305 G, known for its 230-amp DC welding and 10,500-watt AC generator, makes it a go-to choice for many construction professionals.

Automotive Industry: From Frames to Electric Dreams

The automotive sector is a masterclass in precision and efficiency, where every vehicle, from compact cars to heavy-duty trucks, relies on thousands of meticulously placed welds. Modern cars, for instance, utilize over 4,000 spot welds to form their robust frames and join various components. While much of this work happens on assembly lines with robotic welding, there's still a significant need for portable welding in maintenance, custom fabrication, and specialized repairs.

Welder generators are invaluable for mobile repair services, custom shops, and even race teams needing to make quick fixes trackside. They provide the power for MIG welding on body panels, TIG welding for intricate exhaust systems, or even stick welding for chassis repair. The rise of Electric Vehicles (EVs) introduces new challenges and opportunities, requiring advanced techniques like laser and friction stir welding for lightweight metals such as aluminum and high-strength steel. While these advanced methods often require specialized equipment, portable units capable of powering compatible welders or tools remain crucial for surrounding fabrication and repair tasks.

Aerospace & Aviation: The Sky's the Limit

In aerospace, failure is not an option. Welding in this industry is a high-stakes game, demanding absolute perfection for aircraft structures, engine components, and satellite systems. Every joint must be flawless, possessing exceptional strength and fatigue resistance to withstand extreme conditions. This sector predominantly uses highly specialized processes like TIG, laser, and electron beam welding for lightweight alloys such as aluminum and titanium, which often require precise, stable power.

While the most advanced welding is done in controlled environments, welder generators still play a role in fabricating ground support equipment, repairing hangers, or performing field modifications where grid power might be limited. The rigorous standards, like AWS D17.1, mean that any equipment used, even for ancillary tasks, must be reliable and capable of supporting exacting procedures. For high-end, demanding applications, units like the Miller Electric Big Blue 400 Pro, with its 400-amp DC welder and 12,000-watt AC generator, provide the exceptional performance needed to support such critical operations.

Shipbuilding & Marine Industry: Conquering the Seas

Building ships, submarines, and offshore platforms means dealing with immense scale and harsh, corrosive environments. The structural integrity of these vessels depends entirely on incredibly strong, watertight, and corrosion-resistant joints. Welder generators are indispensable here, enabling on-site fabrication and repair of hulls, decks, and intricate pipe systems, often within the vast confines of shipyards or out at sea.

Common welding methods in marine environments include MIG, flux-cored arc welding (especially for heavy sections and outdoor use), and even specialized underwater welding for repairs on submerged structures. The need for mobility is clear; a ship isn't coming to a power outlet. Units must be durable enough to withstand sea air and constant use. Robotic welding is also increasingly used for large-scale sections, but portable units are always on hand for custom fits, repairs, and smaller components. For compact power and portability without sacrificing capability, the Esab Weldstar 300 with its 300-amp DC welder and 7,000-watt AC generator offers a balanced solution.

Energy & Power Generation: Fueling Our Future

From the vast networks of oil and gas pipelines crisscrossing continents to the complex structures of power plants—including nuclear facilities, wind turbines, and hydropower dams—the energy sector relies heavily on welding. The stakes are incredibly high, as welds must ensure safety and efficiency in high-pressure, high-temperature environments, often adhering to incredibly strict standards like ASME codes for nuclear applications.

Welder generators are critical for fabricating new infrastructure in remote locations, performing maintenance on existing pipelines, or repairing components at power stations during scheduled outages. Imagine the logistical nightmare of bringing grid power to a remote wind farm construction site for every single weld. These portable units make such projects viable, powering everything from large-scale structural welds to intricate pipe welding.

Manufacturing & Heavy Industry: Precision and Production

The manufacturing sector, encompassing everything from heavy machinery production to consumer goods, is a massive consumer of welding services. Here, welding is all about precision, speed, and repeatability. Welder generators primarily support fabrication shops, on-site equipment repairs, and facilities where specific welding tasks need to be performed away from fixed welding stations.

MIG, TIG, and resistance welding systems are widely used, often automated with robotics to ensure consistent quality and high production speeds. However, when a custom jig needs to be fabricated, a piece of heavy equipment requires a quick repair on the factory floor, or a field installation demands welding, portable power is key. Hybrid manufacturing, which combines welding with 3D printing, is an exciting emerging trend, creating complex components that push the boundaries of design and functionality. For facilities needing reliable power for various tasks, models like the Hobart Champion Elite (225-amp DC welder, 11,000-watt AC generator) offer robust performance for demanding applications.

Choosing Your Power Partner: Key Selection Factors

Selecting the right welder generator isn't a one-size-fits-all decision. It involves carefully balancing your specific needs with the unit's capabilities. Think of it like choosing a multi-tool; you need the right set of features for the jobs you tackle most often.

Here's a breakdown of the critical factors:

- Power Output (watts) & Welding Capacity (amps): This is foundational. The wattage determines how many tools or appliances you can power, while the amperage dictates the thickness of material you can weld and the types of welding processes you can use effectively. Higher values generally mean more versatility and reliability for demanding tasks.

- Fuel Efficiency & Runtime: Crucial for managing operating costs and minimizing interruptions. Diesel units often offer superior fuel efficiency for prolonged use, but gasoline models are typically more affordable upfront. Look for specifications on how long the unit can run on a full tank at a given load. This directly impacts your productivity, especially in remote areas.

- Weight & Portability: Are you moving it across a vast construction site or just between bays in a shop? Lightweight and compact designs are easier to transport, reducing operator fatigue and increasing overall productivity. Consider if you need wheels, lifting eyes, or a unit light enough for two people to carry.

- Durability: Your welder generator will likely face tough conditions. Look for robust construction, protective frames, and high-quality components that can withstand dust, moisture, and impacts. This directly impacts its lifespan and long-term performance.

- Duty Cycle: This critical spec indicates how long the generator can operate at its maximum output within a 10-minute period before needing to cool down. For example, a 60% duty cycle at 200 amps means it can weld at 200 amps for 6 minutes, then needs 4 minutes to cool. Matching the duty cycle to your typical welding intensity prevents overheating and damage.

- Welding Process Type: Do you primarily use MIG, TIG, or stick welding? Ensure the generator is compatible with your preferred process. Some units are multi-process, offering greater flexibility. Understanding choosing the right welding process for your project is key here.

- Voltage & Current Output: This dictates what specific welding equipment and auxiliary tools the generator can power. Most provide 120V and 240V AC output for tools, alongside the DC output for welding.

- Noise Level & Vibration: Especially important if working in residential areas or enclosed spaces. Lower noise levels (measured in decibels, dB) enhance operator comfort, reduce fatigue, and minimize environmental impact. Inverter-based units often shine in this regard.

- Start-Up & Control System: Look for user-friendly features like electric start, clear digital control panels, and intuitive settings. These reduce operator error, increase efficiency, and make the machine more pleasant to use.

- Safety Features & Certifications: Non-negotiable for operator protection and equipment longevity. Essential features include overload protection, thermal shutdown (to prevent overheating), ground fault circuit interrupters (GFCI) on outlets, and low oil shutdown. Always check for certifications like UL. Proper grounding and ventilation are also critical when operating any welder generator, a core aspect of critical welding safety practices.

- Price: Welder generators span a wide price range. Your budget will influence your options, but remember to balance cost with the features and quality needed for your applications. Sometimes, a slightly higher upfront investment in a durable, feature-rich model saves money in the long run.

- Warranty, Customer Support, & Manufacturer Reputation: These factors provide peace of mind. A strong warranty and responsive customer support indicate a manufacturer's confidence in their product and their commitment to their customers. Brands like Lincoln Electric, Miller, and Hobart have built reputations for reliability over decades.

Types of Portable Welder Generators

The market offers several types, each with its own advantages:

- Gas-powered: The most common and often the most affordable, typically running on gasoline or propane. They offer high power output and are popular for general-purpose use.

- Diesel-powered: Known for their exceptional fuel efficiency, long engine life, and robust performance under heavy loads. They are generally more expensive but can be a better long-term investment for consistent, heavy-duty applications.

- Inverter-based: These units use advanced electronic circuitry to produce clean, stable power. They are typically lighter, quieter, and more fuel-efficient than conventional models. This clean power is ideal for sensitive electronics and offers smoother arc characteristics for welding, making the advantages of inverter technology significant for modern welders.

- Hydraulic & Battery-powered: Less common for standalone welder generators but gaining traction. Hydraulic units are often PTO-driven from vehicles, offering high power with less maintenance. Battery-powered options provide low noise and zero emissions, ideal for indoor work or environmentally sensitive areas, though they currently offer less runtime and power than combustion engines. These options are often part of broader portable power solutions.

Keeping Your Workhorse Running: Essential Maintenance

Just like any valuable piece of equipment, a welder generator thrives on regular care. Neglecting maintenance can lead to costly breakdowns, reduced efficiency, and even safety hazards. Think of it as preventative medicine for your machine.

Here are the key steps for essential maintenance for your unit:

- Oil Checks and Changes: Regularly check your engine oil level and clarity. Replace the oil according to the manufacturer's recommended schedule, typically every 50-100 hours of operation, or at least annually. Clean oil is vital for engine longevity.

- Air Filter Inspection: A clogged air filter chokes the engine, reducing performance and increasing fuel consumption. Inspect it frequently, especially in dusty environments, and clean or replace it as needed.

- Spark Plug Inspection: For gas engines, regularly check the spark plug for wear, carbon buildup, or damage. Clean or replace it to ensure efficient combustion and easy starting.

- Fuel System Check: Inspect fuel lines for cracks or leaks. Ensure the fuel filter is clean to prevent contaminants from reaching the engine. Use fresh, stabilized fuel to prevent carburetor or injector issues.

- Electrical System Check: Periodically inspect all electrical connections for corrosion or looseness. Ensure all safety features, like GFCI outlets, are functioning correctly.

- Consult the Manual: Always refer to your specific model's owner's manual for detailed maintenance schedules and instructions. Using genuine manufacturer parts is also recommended for optimal performance and warranty compliance.

If you encounter malfunctions or unusual performance, always consult your documentation or a qualified repair technician. Don't attempt repairs beyond your skill level, as this could lead to further damage or safety risks.

Emerging Trends Shaping the Welding Landscape

The welding industry is far from stagnant. Technological advancements are continually pushing the boundaries of what's possible, influencing how welder generators will integrate into future workflows.

- Automation & Robotics: The automated welding market is booming, projected to reach $14.5 billion by 2028. Robots and collaborative robots (cobots) are revolutionizing manufacturing by improving precision, speed, and safety, while significantly reducing labor costs. While welder generators typically support human-operated processes or smaller automated cells, their ability to provide stable power to control systems and robotic arms in non-grid environments will be increasingly valuable for mobile robotic welding units or temporary automation setups.

- Artificial Intelligence (AI) & IoT Sensors: The integration of AI and IoT sensors is transforming welding quality and efficiency. These smart systems monitor welding parameters in real-time, detecting and correcting defects, predicting maintenance needs, and optimizing processes for peak performance. Imagine a welder generator that can communicate its fuel level, engine health, and even welding arc quality directly to your smartphone or a central monitoring system—that future is already here or rapidly approaching.

- Green Manufacturing Practices: Environmental responsibility is a growing concern. The welding industry is responding with a focus on low-fume electrodes, lead-free solders, and more energy-efficient equipment. Welder generator manufacturers are also contributing by developing more fuel-efficient engines (especially in inverter models), exploring alternative fuels, and improving emission control systems. This aligns with a broader industry push for sustainable practices that reduce environmental impact and improve worker safety.

Making the Right Choice: Factors Influencing Welding Method

Beyond the choice of generator, the welding method itself is a critical decision that depends on several factors:

- Material Type: Different metals react differently to heat. Aluminum and titanium, for instance, often require TIG or laser welding, while steel is highly versatile and can be joined with MIG, stick, or flux-cored.

- Required Joint Strength & Quality: Critical applications like aerospace or structural construction demand incredibly strong, defect-free welds. This often dictates more precise methods and rigorous inspection.

- Project Size & Scale: Large-scale, repetitive projects often benefit from automation (MIG, robotic welding), while smaller, custom jobs might favor the flexibility of stick or TIG.

- Cost Constraints & Production Speed: Some methods are faster and more economical for high-volume production, while others are slower but offer superior quality for specialized tasks.

- Environmental Regulations: Concerns about fumes, noise, and energy consumption can influence the choice of welding process and equipment, especially in sensitive environments.

- Certifications: Adherence to standards from organizations like AWS (American Welding Society), ASME (American Society of Mechanical Engineers), OSHA (Occupational Safety and Health Administration), and ISO (International Organization for Standardization) ensures safety, quality, and compliance in most industries.

Powering Your Next Project with Confidence

From the rugged demands of a remote construction site to the precision needed in a specialized fabrication shop, welder generators are more than just tools—they are essential partners. They embody the spirit of mobility and self-reliance, empowering skilled professionals to tackle diverse projects regardless of location.

By understanding the specific applications across industries, the various types available, and the crucial factors that go into selecting the right unit, you're well-equipped to make an informed decision. Remember, the right welder generator isn't just about raw power; it's about reliable performance, safety, and ultimately, boosting your productivity and expanding your capabilities. Invest wisely, maintain diligently, and you'll find these versatile machines to be an indispensable asset, powering your success for years to come.